Tiger Casting Solution Sdn Bhd

is providing all your casting and machining needs

Engineering solutions for all industries

Tiger Casting Solution Sdn. Bhd. was established in July 2009. Tiger business span is manufacturing of steel castings concentrating in low alloy steel, nickel chrome moly steel, high chrome moly steel and manganese steel.

Our castings serve various industries globally such as Ground Engaging Tools casting and manganese casting for mining industry, wear parts for quarry industry, selected steel material properties casting for forestry industry and general engineering.

Mining Industry

Oil & Gas Industry

Forestry Industry

Construction Industry

Add Your Heading Text Here

ISO 9001 quality management certified

We are ISO 9001 quality management certified. We firmly believe good quality assurance and quality control in our processes are the main drive to success to supplying good quality casting to the industries. We share, work closely and providing effective casting solutions to our customer in a way to achieve greater performance and productivity together.

Our Core Strength

Sand casting and investment casting are both methods used in the manufacturing industry to create metal parts.

Sand casting is one of the oldest and most versatile methods of metal casting. It involves creating a mold made of sand, which is packed around a pattern of the desired object.

Investment casting, also known as lost-wax casting, is a precision casting process that has been used for centuries. It allows for the production of parts with intricate shapes and high dimensional accuracy.

Heat treatment, casting gauging, and quality control are vital for ensuring high-quality cast metal components.

Heat treatment enhances the mechanical properties and performance of castings through controlled heating and cooling processes.

Casting gauging involves measuring and inspecting cast metal components to ensure they meet dimensional and quality specifications, crucial for verifying accuracy before further manufacturing.

Quality control (QC) includes systematic processes to monitor, evaluate, and enhance the quality of cast metal components throughout production, aiming to prevent defects and ensure consistency.

Tooling design in metal casting refers to the creation of molds, patterns, and core boxes that are used to produce cast metal components. It involves designing and manufacturing these tools to ensure accurate and efficient production of castings.

Precision machining is the process of removing material from castings to achieve tight tolerances, smooth finishes, and specific geometrical shapes. It is often required to refine cast components for final assembly or functional use..

Sand Casting & Investment Casting

Sand Casting & Investment Casting Heat Treatment, Casting Gauging & Quality Control

Heat Treatment, Casting Gauging & Quality Control Tooling Designed & Precision Machining

Tooling Designed & Precision MachiningSustainability

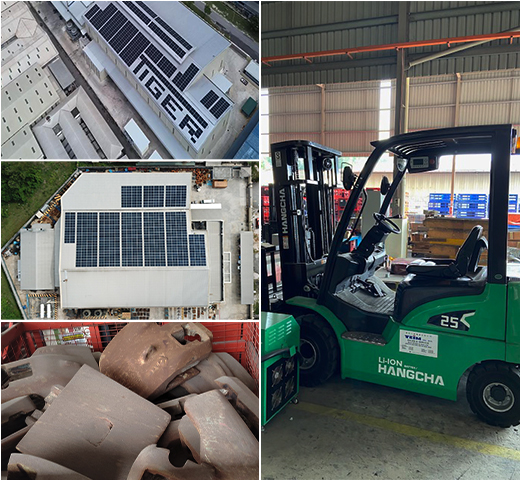

We are committed to environment protection and energy efficiency through a sustainable casting manufacturing processes up to recycling of used castings from our customers. We have invested in solar system for both plants to hardness renewable power.

A program to replace diesel forklift with electric forklift that not only reducing gas emission, is also lowering noise pollution. Furthermore, our manufacturing process energy source are Liquefied Petroleum Gas (LPG) and Liquefied Natural Gas (LNG), results in fewer emission of air pollutants and carbon dioxide.

Solar system

Recycling program with clients

Replacing diesel forklifts with electrical forklifts

Switching from LPG to LNG

Our latest news