Quality Assurance & Quality Control

Quality System

We are ISO 9001:2015 certified company. Plant 1 is fully ISO quality system certified facility. We are in progress obtaining ISO 9001 certification for our new foundry.

We have strict control over all our processes, from raw material purchases, from moulding, melting to pouring, from heat treatment to casting finishing and dimension as control to correct specification. We commit to ensure we meet the quality expectation for our customers.

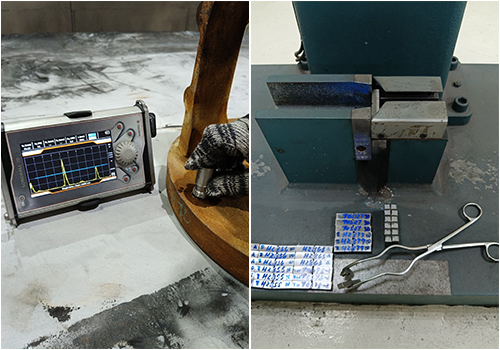

Magnetic Particle Inspection, Dye Penetrant Inspection and Ultrasonics Testing

Our inspectors were trained and having the certification levels to carry out the compliance requirements

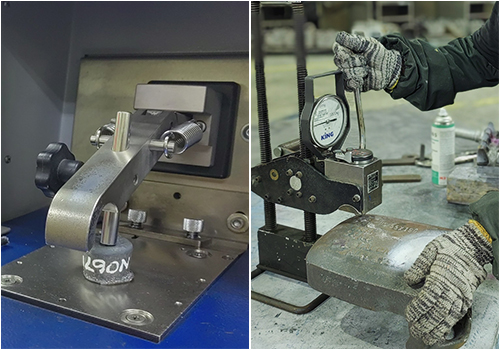

Hardness Check

Hardness check is important for castings. Our hardness testing machine is calibrated and maintain in good condition.

Dimension Control

Dimension Control with correct measuring equipment and gauges are control and practicing correctly by our QC inspectors to achieve dimensional consistency for our manufactured castings.

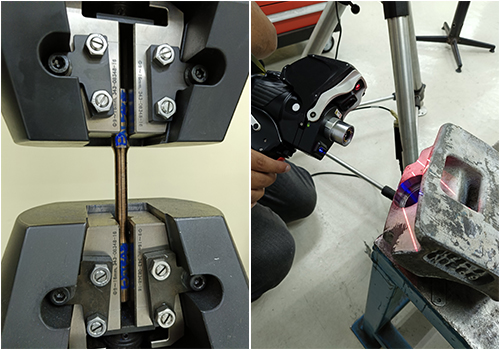

Spectrometer Material & Mechanical Properties Testing Laboratory

Our facilities include a comprehensive tensile and charpy impact strength testing lab, allowing us to evaluate the mechanical properties and toughness of our material under various condition. Assisting customers in material choice. All our testing result are documented as per our ISO documents system.

3D Scanning.

We utilize advanced 3D scanning technology for dimension checking and verification. We have good FAI control system. Our engineers well trained with experience to understand all engineering drawings, handling the 3D scanning software and hardware confidently.

Traceability is Important

Each casting is cast with its unique heat number for traceability. Additionally, each melt will have cas with test bar for use in mechanical properties testing aspect. Each melt have material test button to make sure actual melt spec are conformed to the customer required spec. The test bar will retain for 2 years and test button will retain for 3 years for future reference as per our ISO9001 quality system.