About Us

We specialize in producing high quality low alloy steel castings, including manganese steel and stainless steel, with a production capacity of 5000 ton per annum. We cater to industries such as mining, forestry and heavy machinery, providing tailored solutions to meet their unique demands. Our ISO certified processes and commitment to sustainability ensure that we deliver exceptional products while minimizing our environmental impact.

To be the trusted partner of our customers by delivering superior steel casting products through continuous improvement and innovation in our processes.

To produce steel casting products through sustainable practices, minimizing our environmental footprint, fostering a culture that values safety, responsibility and continuous improvement, while supporting our customers’ needs.

Recycling program with clients

Replacing diesel forklifts with electric forklifts

Our Capacity

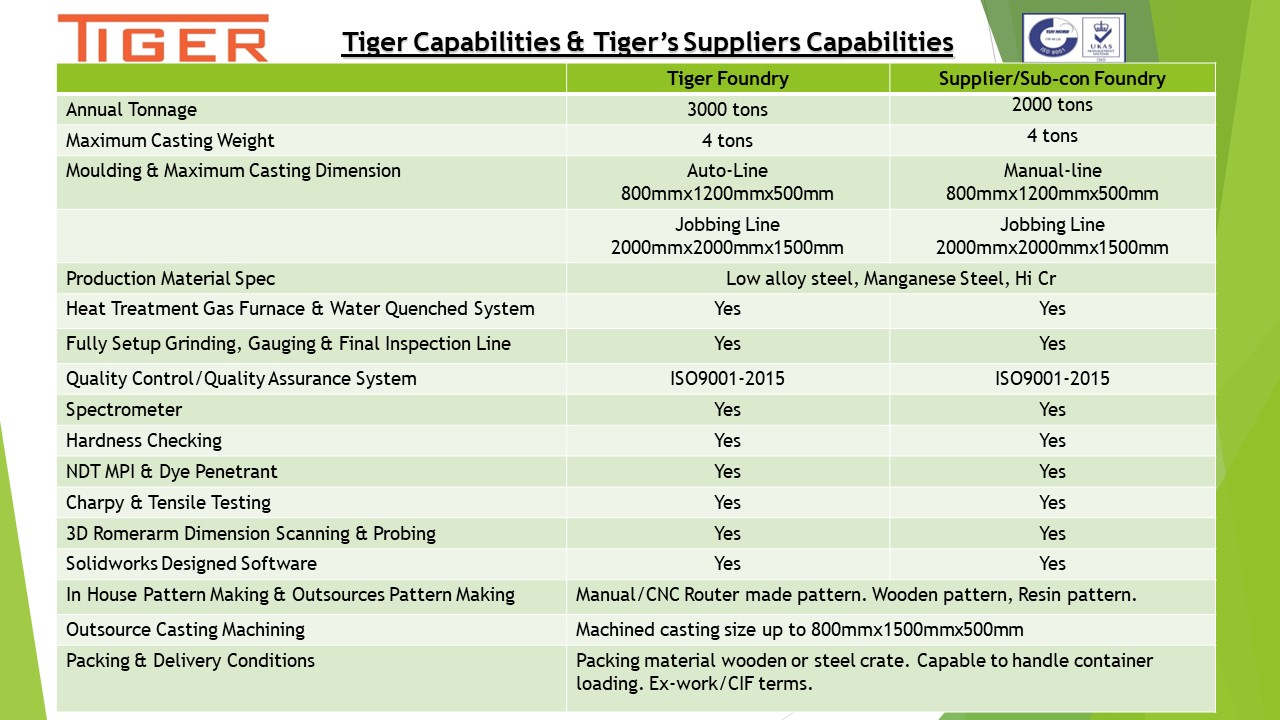

Tiger 1 is currently supplying more than 3,600 tons annual casting to the industry. Tiger 2 our new foundry is designed for an annual production capacity of 3,000 tons in its initial phase and have the plans to expand to 5000 tons in phase two in the future. With two manufacturing plants, we are confident we can continue expand the current production capacity to 8,000 tons of casting annually.

3600

5000

Decades of experience

Adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim.

Our Foundry Equipment and Capability

Molding

Sinto Omega Carousell molding system with rollover machine and flow coating.

Sand Reclamation System

is equipped with chromite separator and secondary attrition units.

Melting

2 units of 3-ton induction furnace

Heat Treatment Furnace

6 units of gas fired heat treatment furnaces, equip with water quenching facilities.

Mechanical Lab

in house charpy impact strength and tensile test.

Final Inspection

in house NDT – UT/DP/MPI

Painting Facilities

designed with a continuous spraying system, equipped with environmental controls for schedules waste collection and air pollution control system.

Delivery

We can handle all types of delivery terms and conditions

Painting Shop

Our painting facilities designed to have a continuous spraying system equipped with environment control for schedule waste collector and air pollution control system